Training & Events

Services > Training & Events

Browse Training & Events

Every individual and operation can improve, and the right training can quickly pay for itself. Choose from options listed below, or design a custom training program for your team. Scroll down this page to learn about the Swagelok Training Advantage. To reach us by phone, please call 510-933-6200.

The Swagelok Training Advantage

Subject Matter Experts

Our trainers have field experience and earn certification by completing hundreds of training hours with internationally renowned experts and passing dozens of exams.

Global Network

Our local trainers are part of a global network of Swagelok-certified trainers. They collaborate to develop new courses, refine course content, gather real world examples, and more.

Broad Capabilities

Our local team includes engineers, tech support gurus, assembly technicians, procurement experts, and more. We strive to integrate all our capabilities to deliver total solutions to you.

Trusted brand

Flexible location

Valuable course materials

Swagelok certificates

Broad application

Easy start

Iffy Skills → More Errors

Many technicians do routine tasks by feel. Connections done that way usually aren't quite right. They may leak sooner, impacting safety, quality, and emissions. Training can lower risk and operating costs right away and over time.

Train to ensure safe, reliable systems

We can enhance seasoned employees' skills and bring newer employees up to speed faster. Choose from options shown on this page or create a custom program to cover small bore tubing systems, regulators, or other fluid system topics. Hold just one event... hold a series of related events... or hold semi-annual trainings. Location is flexible too.

Seminars developed by a trusted brand

A trusted brand stands behind each Swagelok instructor and training event. Swagelok is a $2.4B company founded in 1947. Our quality management systems, values-driven people, and high quality products combine to help ensure consistency and value.

No-risk next step

Thousands of companies have benefited from Swagelok training. Having a conversation with our team about your options creates no obligation or costs. To reach us by phone, please call 510-933-6200.

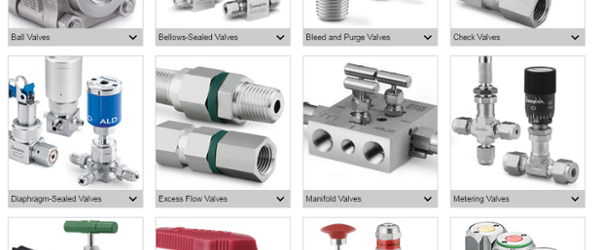

About Swagelok Northern California

Swagelok Northern California provides Swagelok fluid system products, assemblies, and services to California and Nevada companies. Our fluid system engineers, trainers, support specialists, and technicians are devoted to helping busy customers run safe, efficient operations. We have tens of thousands of Swagelok tube fittings, valves, hoses, regulators, tubing, and other types of parts in stock in our local warehouses. Give us a call at 510-933-6200.

Request Information/Support

Need details or a quote? We are ready to help.

.webp?width=210&height=70&name=StickyLogo%20(5).webp)

.jpg?width=600&height=338&name=Thumb_vid_EmpoweringThroughTraining%20(1).jpg)

.jpg?width=600&height=338&name=Thumb_vid_PASSTraining%20(1).jpg)

.jpg?width=600&height=338&name=Thumb_vid_AdvancedBendingTraining%20(1).jpg)